TreadSight™ Dedicated Tire Wear Testing

TreadSight™ Dedicated tire testing offers high operational control, repeatability, and a deeper measurement framework to support confident engineering decisions. In practice, dedicated tire testing uses dedicated test vehicles and defined operating conditions to reduce variability while preserving real-world wear behavior.

Measurement cycle updates are typically uploaded within hours of completed cycles to our secure data portal, with A.N.D.A.S.™ (Automated Data Notification & Alert System) providing automated alerts when new data becomes available for download. This enables engineering teams to review results, validate assumptions, and make informed program decisions throughout the test.

Dedicated programs are structured to balance operational control with real-world mileage accumulation, allowing wear, abrasion, and durability behavior to be evaluated under repeatable routes, loads, and operating targets. This approach supports clearer interpretation of wear trends while maintaining relevance to real-world operating severity.

Best for

- Comparative R&D decisions

Controlled execution to reduce noise and support defensible comparisons. - Compound development & benchmarking

Expanded measurement depth and abrasion efficiency views to interpret behavior. - Programs requiring repeatability

When cycle to cycle consistency and documentation discipline matter.

What you receive

- Cycle-by-cycle + cumulative reporting

Engineering visibility throughout the program via secure portal delivery. - Expanded wear characterization

Multiple wear rate views and trend behavior to support interpretation. - Wear pattern context

Heatmap wear visualization and photo documentation to support technical review.

Data Integrity & Reporting

Field Evaluation Services, Inc. TreadSight™ programs are designed around disciplined data capture, validation, and reporting to support defensible engineering review.

Measurement workflows maintain consistency across defined test cycles, with documentation and reporting structured to preserve data integrity and protect against post collection modification. This approach allows engineering teams to evaluate trends, validate assumptions, and make informed decisions with confidence as testing progresses.

Representative Dedicated Tire Wear Testing Deliverables

The deliverables listed below are included as part of all TreadSight™ Dedicated Tire Wear Testing programs. They represent a portion of the standard reporting framework and illustrate typical data depth, structure, and review frequency. Additional measurements, analyses, and reporting elements are incorporated based on specific program objectives.

- Cumulative and cycle based wear reporting

Wear metrics reported both cumulatively and on a cycle by cycle basis, expressed in imperial and SI units. - Wear metrics in multiple engineering views

Average mm loss per 1,000 miles / km, FWG mm loss per 1,000 miles / km, miles per mm, miles per 32nd, kilometers per mm, percent worn (tire average and by groove). - Cycle to cycle deltas (trend behavior)

Cycle over cycle deltas support earlier visibility into accelerating, decelerating, or stable wear trends. - Mileage projections with transparency controls

Tread loss projections derived from measured wear rates, regression based projections are provided only when statistical criteria are met, with outputs explicitly flagged when criteria are not satisfied.

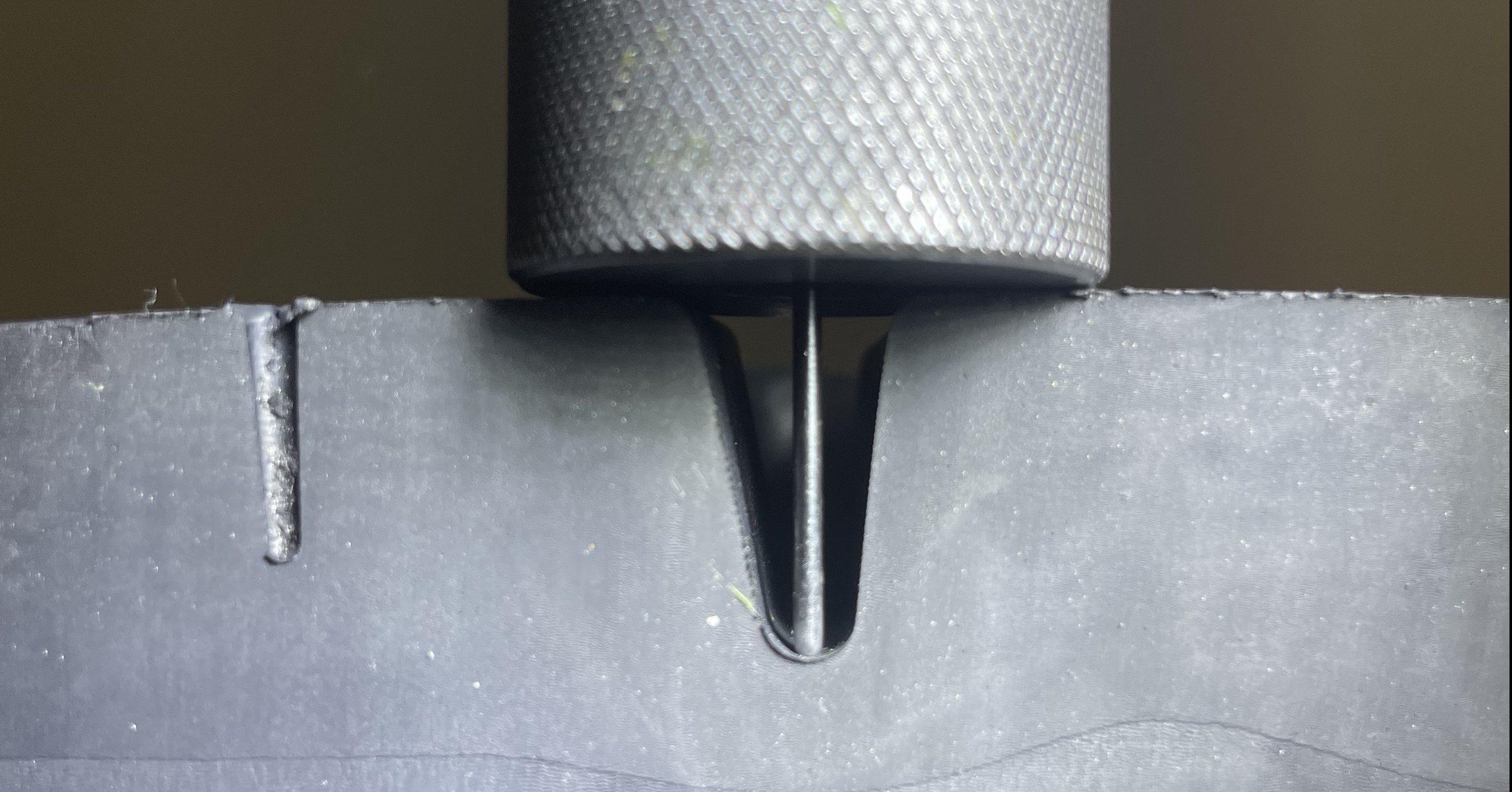

- 3D tread scanning for wear pattern visualization

To capture tread geometry changes, each measurement section is 3D scanned at the start and end of the test, with deviation based heatmaps generated to support interpretation of localized wear and wear pattern distribution. - Non-uniform wear visibility

Outputs support review across the tread face where applicable, beyond single value wear rate. - Tire mass tracking

Tracks material loss alongside tread depth wear rates and supports iTAS™ / mTAS™ abrasion reporting. - Tire photo documentation

Cycle based photographic documentation including tread face per measurement section, sidewall condition, and observed anomalies to support engineering review.

iTAS™ & mTAS™

TreadSight™ Dedicated Tire Testing includes our iTAS™ and mTAS™ abrasion efficiency indicators, adding a material focused view of tire rubber usage efficiency for compound comparison and benchmarking. These indicators complement tread depth based wear rate reporting.

Calculation methodology and collection process remain proprietary. Reporting format and scope are defined per program.

Program Control That Supports Cleaner, More Defensible Tire Wear Data

Dedicated testing programs are structured to minimize uncontrolled variables while preserving real-world operating conditions. Route selection, mileage accumulation rates, vehicle selection and configuration, load targets, inflation control, and defined measurement intervals are intentionally set to support repeatable tire wear testing and abrasion analysis.

-

Nationwide program deployment with controlled remote execution (U.S. + Canada)

Where required, programs can be deployed across the United States and Canada to align with client specific duty cycles, routes, environmental conditions, or regions associated with elevated tire warranty activity. When execution occurs outside of primary operating locations, Remote Support Units (RST) are used to preserve facility equivalent execution, including documentation workflows, defined measurement intervals, connectivity, and secure data portal upload expectations. -

Coachella Valley desert base

A primary operating base in California’s Coachella Valley provides a naturally repeatable environment for accelerated tire wear testing. Summer daytime temperatures routinely average 110–120°F, combined with ultra-low humidity, minimal rainfall interruptions, intense UV exposure, and abrasive road surfaces, supporting controlled hot weather wear and abrasion work without reliance on artificial proving ground surfaces. -

Rapid mileage accumulation & precision control

When rapid mileage accumulation is required, programs can be structured for high daily mileage throughput. On select, validated routes, sustained accumulation of up to approximately 1,500 miles within a 24-hour period can be achieved when program objectives support accelerated testing. For abrasion efficiency and wear pattern studies, daily mileage is intentionally controlled to help maintain consistent tire operating temperatures and reduce environmental variability. If existing routes do not align with specific duty cycle, load, or operational requirements, custom tire testing routes can be developed to suit program specific objectives.

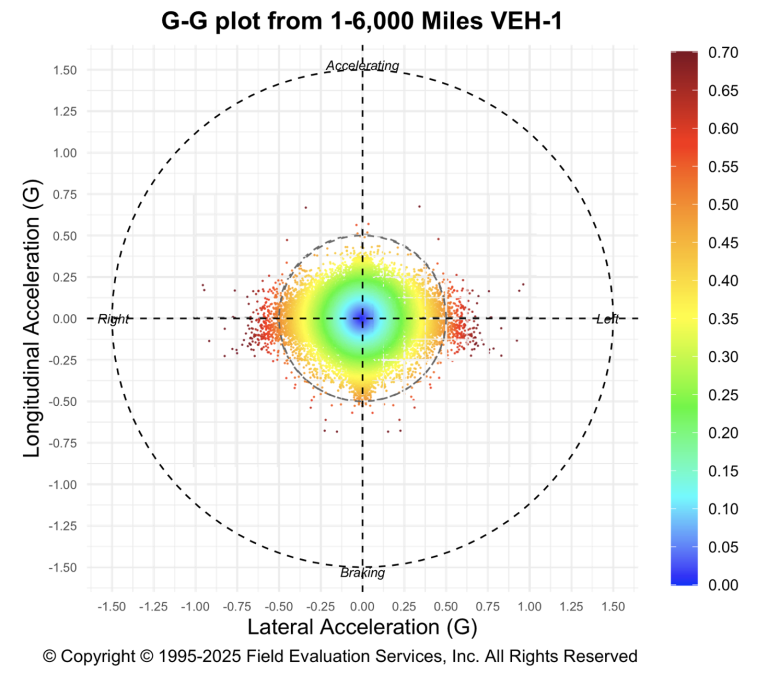

Designed for duty cycles driving EV tire wear

EV duty cycles introduce wear mechanisms that differ materially from ICE vehicles. Higher vehicle mass, immediate torque delivery, and regenerative braking place increased stress on tread compounds, contact patch stability, and abrasion efficiency, accelerating wear under real-world operating conditions.

TreadSight™ Dedicated Tire Testing is structured to support clear interpretation of EV specific wear behavior through controlled execution, repeatable routes, and expanded measurement depth. Program design evaluates the wear response of tires operating under EV duty cycles characterized by high torque application, vehicle mass, and regenerative braking, allowing tread wear progression and wear pattern distribution to be assessed across defined test cycles.

The Coachella Valley support sustained EV tire testing through mature super charging availability, enabling high uptime operation without compromising route consistency, cycle flow, or test objectives. In addition, California represents the largest EV replacement tire market in the United States, making real-world wear data generated under these duty cycles directly relevant to aftermarket and durability focused engineering decisions.

-

Hot weather real-world exposure

When aligned to program objectives, controlled hot weather exposure supports development work where temperature driven wear behavior is a priority. -

Wear pattern interpretation

3D wear visualization and photographic documentation support interpretation when non-uniform wear behavior is part of the engineering question.

-

Abrasion efficiency context

Tire mass tracking and iTAS™ / mTAS™ reporting add a material efficiency view alongside depth based wear rates. -

Program design aligned to validation objectives

Scope, measurement depth, and reporting outputs are defined to support objective validation and defensible engineering review.

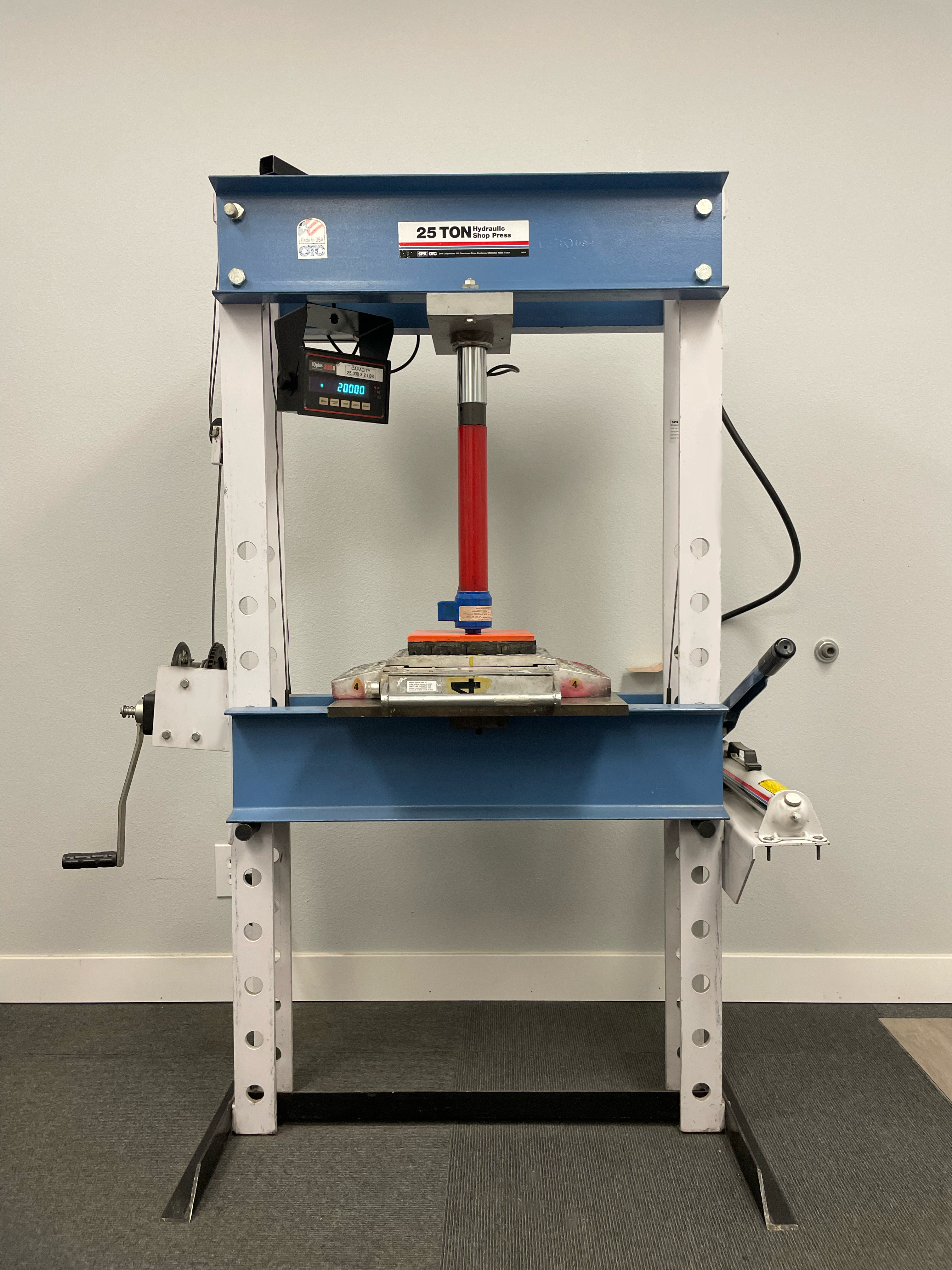

Verification practices that support defensible data

TreadSight™ Tire Wear Testing projects incorporate routine verification practices to maintain measurement integrity across tread depth, mass, pressure, and hardness measurements. These checks support consistency across measurement cycles, vehicles, and execution locations.

- Scale verification

Vehicle and floor scales verified using calibrated and traceable reference methods. - Pressure verification

TPMS sensors and air gauges verified against calibrated master references. - Durometer verification

Shore A gauges checked using standardized hardness reference blocks. - Tread depth gauge verification

Tread depth gauges verified using hardened calibrated reference blocks before and after measurement activity.

Define the engineering question. We’ll structure the program to answer it.

Dedicated Testing is structured around a clearly defined validation objective. Scope and deliverables are configured to produce accurate, traceable data suitable for technical review, comparison, and decision support.